|

| February 26, 2013 | Volume 09 Issue 08 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

How engineers are reinventing the automobile with embedded systems

[Image: National Instruments]

Embedded software takes automobile design into the future.

By Noah Reding, Automotive Industry Product Manager, National Instruments (NI)

Why are we so fascinated with the automobile? It's certainly more than the practicality that comes with getting from place to place. And we know it's more than challenging the capability of the speedometer on an open road, too. It's more than a car -- it's the consummate innovation platform housing centuries of engineering feats from the first steam- powered vehicle to modern cars that can parallel park themselves.

The next major wave of change in the automotive industry is arriving right now, and it's driven largely by embedded software. The presence of embedded software in your vehicle is completely revolutionizing the way cars operate, not to mention the way they're designed, developed, and tested. Think about the air-to-fuel mixture in your engine. Years ago, you took out your toolbox and tweaked the carburetor until it was just right.

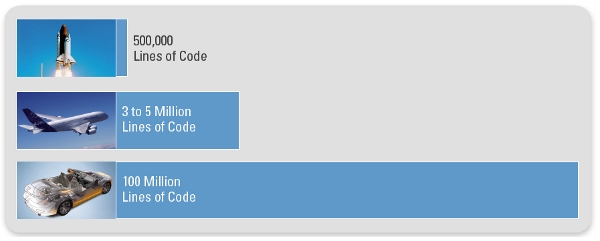

When you look at the amount of code that goes into other advanced machines, you can begin to visualize the electronic complexity of a modern vehicle. [http://spectrum.ieee.org/green-tech/advanced-cars/this-car-runs-on-code]

Today, it's a completely different story. The air-to-fuel ratio in your car is controlled by an electronic control unit (ECU), which is an onboard computer making decisions regarding how your car will run. Drivers are increasingly relying on embedded software to not only make sure vehicles function properly but also diagnose and fix them when they don't. As electronically complex as vehicles are now, this is no small challenge for the engineering community. As a point of reference for this complexity, the space shuttle might have about 500,000 lines of software code in it, and estimates put modern luxury vehicles at up to 100 million lines of code.

To help the automobile maintain its claim as the most innovatively engineered machine of all time, developers are integrating embedded software into virtually every part of the automobile creation process.

The continuing electrification of the automobile

Gas is expensive and most natural resources are finite, so it should come as no surprise that one of the biggest ways engineers are changing the future of the automobile is through electrified vehicle powertrains. Rising fuel costs and efforts to decrease individual carbon footprints have put the pressure on manufacturers to produce alternatively powered vehicles, which are fundamentally different from traditional combustion engines.

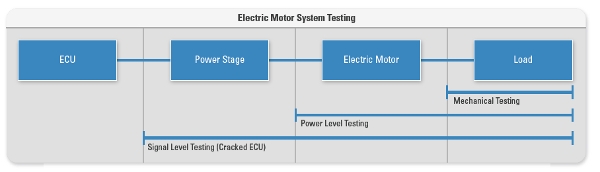

These new designs are challenging for development teams because even though traditional combustion engines also use embedded software to control key components, electrified powertrains introduce completely different obstacles. For example, the traditional tools used for validating software through hardware-in-the-loop (HIL) simulation, which simulates components with complex algorithms or models, don't provide as much insight and value when used on electric motor systems. This lack of insight comes from technical differences, such as needing to simulate pulse-width modulation (PWM) signals 10 times faster, and test systems that have to handle high-voltage values on the order of a few hundred volts.

Depending on the simulated parts of the system, these requirements are non-negotiable if you want to achieve high-fidelity results. Traditional HIL tools simply don't provide the necessary accuracy to validate modern electrified systems. This forces more and more companies to evaluate high-performance HIL platforms with advanced technologies like field-programmable gate arrays (FPGAs) to ensure that their simulation models are executed at the faster speeds needed.

54.5 mpg by 2025: Let a computer do the math

Shifting gears from electric to combustion engines, consider enhancing fuel economy. You'll still find this trend being driven by fuel cost and environmental concerns, but those factors are coupled with aggressive legislation. For example, the United States set a goal for vehicles to get an average of 54.5 MPG by the year 2025. For most cars on the road today, a number as high as 54.5 is shocking.

In combustion vehicles, ECUs use algorithms to ensure that the right air-to-fuel ratios are sent to the engine to achieve proper gas mileage while meeting emissions restrictions. The need to constantly prototype, test, and perfect these algorithms to meet extremely aggressive fuel economy goals results in added pressure for ECU software developers.

Automotive engineers need flexible prototyping platforms that combine simulated system components with actual physical components throughout different testing stages.

They have to innovate and iterate incredibly fast, which means they need flexible prototyping platforms that combine modular I/O with the ability to run simulation models in real time. Of the many parts of the embedded ECU software, the control algorithm is most critical to making the right decisions based on incoming data. For example, algorithms have become significantly more complex due to the growing popularity of direct injection in production engines. Since direct injectors supply fuel into the harsh environment of the engine cylinder immediately before combustion, extremely precise computations and feedback from numerous advanced pressure sensors must be taken into account for each engine cycle. For a V8 engine running at 6,000 RPMs, an ECU would need to make this calculation and actuality in less than 3 msec.

Part mechanical. Part virtual. Shifting the testing paradigm.

As previously mentioned, HIL testing simulates system components with models instead of physical components to decrease overall test and validation costs. Another type of traditional testing in the automotive industry involves using physical and mechanical components like dynamometers in a test cell.

However, you can apply the same benefits that you gain from using simulation models with HIL testing to mechanical testing in test cells. For example, it is becoming more common to see a test cell that combines models with actual physical components to test a device like an ECU, often called a model-based test cell. This shifts the traditional testing paradigm and forces engineers to combine testing methodologies in this stage of embedded software validation.

Driven to distraction: Software to control infotainment and driver behavior

The most frequently advertised modern vehicle features deal with infotainment and advanced driver assistance. Embedded software plays a critical role in displaying information, connecting to external devices, detecting potential problems, and correcting driver behavior. As the line between your cellphone and vehicle continues to blur, the software that controls your in-vehicle entertainment system and potentially saves your life by detecting if you veer out of your lane or fall asleep will continue to advance.

In addition to the rising amount of software these features require, these systems use a wide range of I/O and must be efficiently tested. For example, testing a system that communicates over a variety of RF protocols, features a combination of in-vehicle networks, and takes input from distributed sensors can be incredibly complex. At the same time, some of this I/O hasn't been historically common for the industry, which means there's often a steep learning curve when testing the system requirements. One way to address that curve is to use a platform that synchronizes all of your I/O in a single system sharing the same timebase. Simultaneous testing on all of this rapidly evolving I/O provides the most complete, accurate picture of what is going on in the car.

Safety first: A more secure ride through software

Passenger safety is one of the most important focus areas for engineers improving the automobile -- not only for the emotional aspect of protecting friends and family, but for the massive software challenge it presents. The number of safety-critical components controlled electronically in vehicles has grown exponentially, which means testing to ensure the functionality of all those components has scaled as well.

As your dashboard becomes a hub for both entertainment and information, embedded software will play a critical role in how your car behaves.

A recent effort by the automotive industry to ensure that cars are developed with safety in mind is the ISO 26262 functional safety standard. Similar to safety standards in other industries such as aerospace, ISO 26262 defines a process for evaluating the impact of electronic components on safety, along with how the components should be developed and tested. New standards inevitably affect project schedules, but by using smart test techniques such as maximizing component reuse, automotive engineers can prioritize consumer safety with ISO 26262 -- without sacrificing the safety of their project schedules.

These and more of the most talked about and innovative features of the modern vehicle are directly affected and controlled by embedded software. However, each of these applications is different and introduces a new kind of challenge. At National Instruments, we see these challenges and are investing to make sure that validating embedded software in all areas within the vehicle can be a productive and efficient process for engineers and scientists in the automotive industry.

Click here to get more technical details on how NI is investing in products to help engineers meet these challenges.

Designfax is proud to be a media partner with National Instruments. This article first appeared in the Q1 2013 issue of Instrumentation Newsletter.

Published February 2013

Rate this article

View our terms of use and privacy policy